Storeroom 4.0™

Transform MRO inventory management with Storeroom 4.0™—advanced tech, real-time tracking, and optimized space for maximum efficiency.

The advent of Industry 4.0 is transforming manufacturing, driven by advanced automation, real-time data, and digital connectivity. This revolution is not just reshaping production lines but also redefining how supporting functions, such as storerooms, operate. Storerooms must now embrace technologies like IoT-enabled devices, predictive analytics, and smart inventory systems to meet the demands of an interconnected and data-driven manufacturing environment. Recognizing this shift, we developed Storeroom 4.0™—a solution designed to bridge the gap between traditional storeroom management and the cutting-edge requirements of Industry 4.0. By integrating advanced inventory systems and point-of-use technologies, Storeroom 4.0™ equips manufacturers with the tools needed to ensure agility, reduce downtime, and enhance operational reliability in an increasingly complex landscape.

Storeroom 4.0™ delivers unparalleled efficiency through a combination of advanced technologies and modernized inventory systems. It ensures optimal performance with minimal resource requirements while enhancing the end-user experience. Combined with our Operational Excellence (OPEX) system, we continuously monitor, assess, and report on every aspect of your storeroom operations, providing full transparency and control.

Stock Data with

>99% Accuracy

>99% Request

Fulfilment Ratio

OPEX for a World Class Storeroom

By outsourcing your storeroom management to RS Integrated Supply, you gain a partner committed to helping you achieve world-class results through innovation and operational excellence.

Services offered

Inventory Data Capturing and Enrichment

We kickstart our services with precise inventory data capturing. Using advanced tools like SnapPart™, we meticulously record every item in your storeroom with manufacturer details, part numbers, and images. This enriched data lays the foundation for improved inventory management and full transparency.

Inventory Optimization

Our data team analyse your inventory to align stock levels with real-time demand. By identifying and eliminating excess stock while ensuring critical items are readily available, we reduce stock carrying costs and improve inventory efficiency.

Critical Spares Identification

We focus on identifying and prioritizing critical spare parts to prevent production interruptions. Our approach ensures that essential components are always available when needed, minimizing downtime and keeping your operations running smoothly.

Storeroom Layout Design

A well-structured storeroom maximizes space efficiency and workflow. Our implementation team designs layouts tailored to your specific operational needs, whether it’s a main storeroom, satellite storeroom, or line-side solution. This ensures optimal accessibility and space utilization.

Point-of-Use Technologies

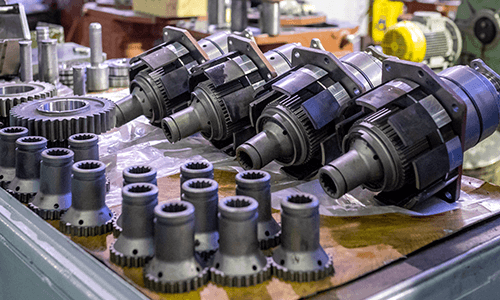

Storeroom 4.0™ integrates cutting-edge technologies like automated dispensing systems and real-time tracking to bring inventory closer to the point of use. This reduces retrieval times, enhances productivity, and ensures materials are available exactly where and when they’re needed.

BENEFITS

Total Control and Transparency

Our Storeroom 4.0™ delivers complete visibility into your inventory. During implementation, every item is carefully recorded using our SnapPart™ technology, capturing manufacturer details, part numbers, and images with over 99% accuracy. This ensures your storeroom and stock data is fully organized and managed with precision.

Optimized Space Utilization

Space is a premium in manufacturing plants. Our Storeroom 4.0™ approach maximizes the efficiency of every square meter, optimizing both storeroom and point-of-use technologies to align perfectly with your operational needs, freeing up valuable floor space for other critical activities.

Optimized Resources

By utilizing advanced technologies such as real-time inventory tracking, automated systems, and Vendor-Managed Inventory (VMI) techniques, we streamline operations and minimize the resources required to effectively manage storerooms.

Reduced Inventory Levels and Costs

Storeroom 4.0™ aligns stock levels with actual demand, eliminating excess inventory and significantly lowering stock-carrying costs, all while ensuring optimal availability to meet operational needs.

Improved Efficiency and Fulfilment Rates

Waiting times for materials are drastically reduced with Storeroom 4.0™ , and the instant fulfilment ratio for stocked material requests is improved to over 99%. This translates to faster maintenance, reduced asset downtime, and enhanced overall operational performance.

Ready to revolutionize your Storeroom Management?

Discover how our Storeroom Solutions® can optimize your MRO inventory, streamline your procurement processes, and elevate operational efficiency. Contact us today to learn more about our tailored solutions and take the first step toward smarter, more efficient inventory management.