Published on

Read time: 2 minutes

The challenge

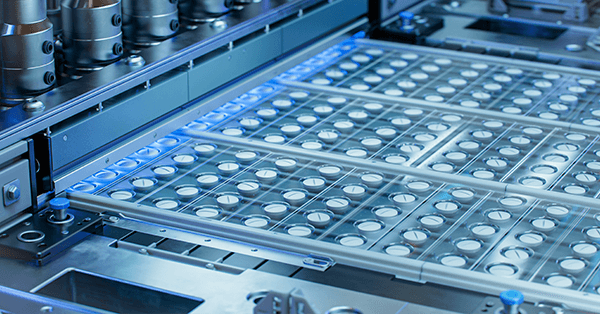

A large life sciences manufacturing company with global reach and based in the U.S. enlisted RS Integrated Supply to bring added value to the company’s existing MRO supply chain program.

With more than 50,000 SKUs and $20 million in spare part inventory spread across a dozen storerooms, the client was looking to take an already strong MRO program to the next level.

A RS Integrated Supply team of 13, including multiple buyers and storeroom attendants, a site manager, and others, worked to build proper processes and establish best practices to further drive down inventory levels without impacting service or creating production downtime.

While the full storeroom management program delivered significant client savings through strategic sourcing, inventory optimization, and enhanced MRO storeroom management, it was clear the conditions required even more attention to meet client expectations.

The solution

RS Integrated Supply introduced a repair program initiative aimed at generating additional savings while staying true to the initial goal of lowering inventory levels. Program implementation began with pre-identifying parts eligible for repair. This step was key to the process, enabling employees to quickly recognize how a failed part was to be managed.

As with any MRO supply chain program, client acceptance and participation are mandatory to achieving desired savings. In this case, client maintenance technicians, engineers, and others had to be convinced that returning eligible parts to the storeroom to initiate the repair process would return value.

It was important to overcome the stigma that repaired parts are less efficient or trustworthy than new parts.