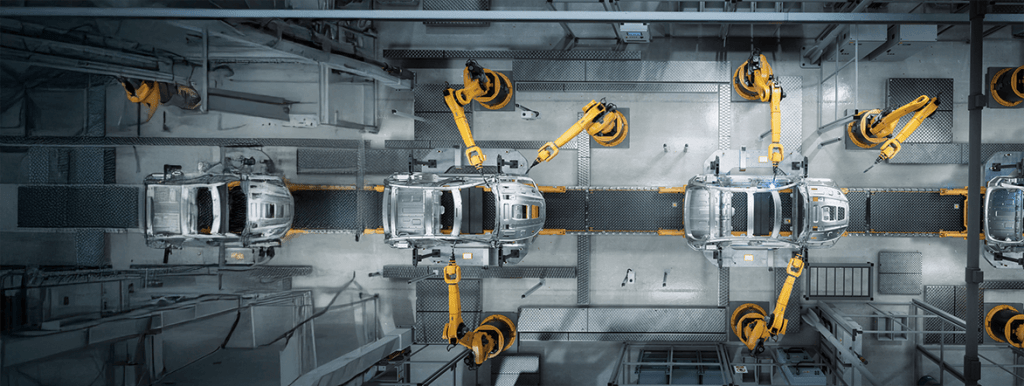

Automotive

Enhance automotive MRO with integrated supply solutions that optimize procurement, inventory, and equipment reliability. Improve efficiency and reduce costs today.

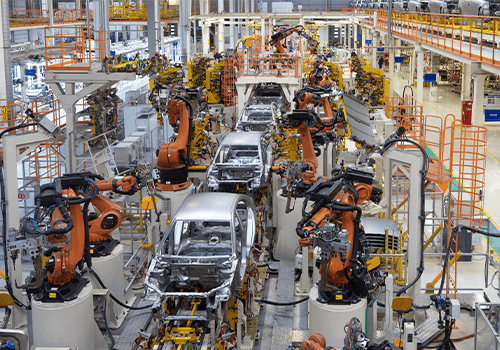

The automotive industry has long been a pioneer in adopting advanced manufacturing methodologies, and none more influential than the Just-in-Time (JIT) production system. Born in the 1970s in Japan, JIT was developed to optimize the production process by reducing waste and minimizing inventory levels. By ensuring materials arrive exactly when needed, JIT allows automotive manufacturers to maintain lean operations, reduce costs, and increase efficiency.

This model revolutionized the way vehicles are produced. It focused on the seamless flow of direct materials, ensuring that production lines never experienced delays due to stockouts or overproduction. The core principle was simple: reduce waste, improve quality, and maintain a steady pace of production.

However, while the JIT system excelled at managing direct materials, there’s another critical aspect of automotive manufacturing that demands the same level of precision and efficiency: MRO (Maintenance, Repair, and Operations) services. In an industry where every minute of downtime can cost millions of dollars, ensuring that the right spare parts and maintenance tools are available at the right time is just as essential as direct material flow.

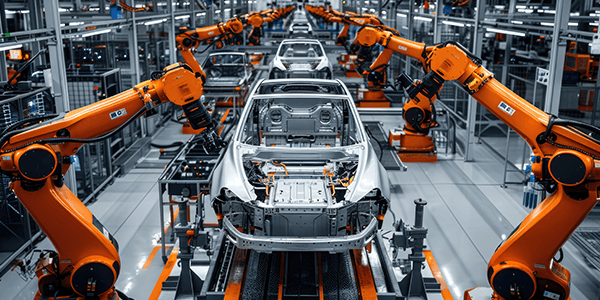

Just-in-Time MRO

At RS Integrated Supply, we understand that Just-in-Time (JIT) goes beyond direct materials—it must also encompass MRO practices to keep your production line running smoothly. In the automotive industry, where every hour of downtime can lead to significant losses, having the right maintenance materials at the right time is essential. Our MRO services are designed to align with JIT principles, ensuring critical spare parts and tools are always available when needed. By optimizing inventory, leveraging demand forecasting, and utilizing point-of-use technologies, we minimize production interruptions and reduce the risk of unplanned downtime, keeping your operations efficient and on schedule.

How We Achieve Just-in-Time MRO

Our approach to Just-in-Time MRO management involves several key strategies to ensure maximum efficiency and minimal downtime:

Optimizing Inventory

Our data-driven approach ensures continuous optimization of inventory levels. Through predictive analytics, we accurately forecast demand and adjust inventory levels accordingly. By minimizing overstocking and preventing stockouts, we strike the right balance between cost-effective inventory management and ensuring the availability of critical parts when needed.

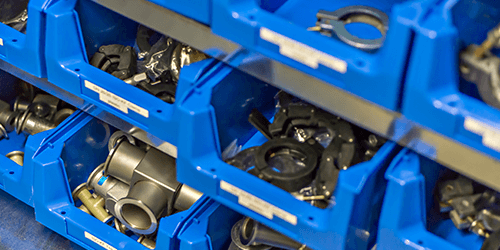

Point-of-Use Technologies

One of the most significant challenges in MRO is the time it takes to collect the required parts. Traditional methods often involve manual retrieval from central storerooms, causing delays and wasting precious time. Our point-of-use technologies eliminate this inefficiency by placing critical parts directly where they are needed—on the production floor. This reduces item collection times, improving the overall efficiency of your operations.

Critical Spares Management

We understand the importance of having critical spare parts available when needed most. By managing these high-demand items through predictive analytics and ensuring they are always stocked in the right quantities, we help prevent production stoppages due to missing or delayed spare parts.

Asset and Spare Parts Management

Our RS SYNC™ platform ensures seamless tracking of assets and spare parts by uniquely identifying and tagging each asset for easy access. We define the Bill of Materials (BOMs) for every asset and identify the necessary spare parts. Within the RS SYNC™ Marketplace, items can be filtered by associated asset, ensuring that the correct spare parts are requested when needed. This approach helps mitigate unplanned downtime and ensures your operations run without interruptions.

Real-Time Data Integration

Our RS SYNC™ platform integrates data across the entire supply chain, providing real-time visibility into inventory levels, procurement status, and maintenance needs. This empowers your teams to make quicker, more informed decisions and respond faster to any issues that arise on the production floor.

A Proven Track Record with Automotive Leaders

At RS Integrated Supply, we don’t just provide MRO services; we are partners in transforming your operations. For years, we have worked with some of the leading automotive manufacturers, helping them convert non-value-adding processes into value-generating practices. By continuously optimizing MRO procurement, improving inventory management, and ensuring just-in-time parts availability, we help automotive manufacturers stay ahead of the competition, reduce operational costs, and improve overall efficiency.

Our commitment to simplifying MRO processes and amplifying operational efficiency means we’re not just keeping the production line moving—we’re driving sustained, long-term growth for your business.

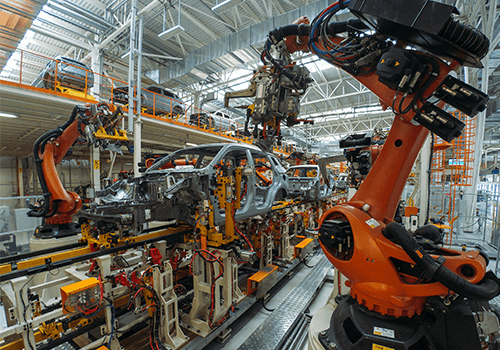

The Future of Automotive Manufacturing: Smarter, Leaner, More Efficient

In the fast-paced world of automotive manufacturing, the importance of Just-in-Time MRO management cannot be overstated. With RS Integrated Supply, you can ensure that your MRO operations are as streamlined and efficient as your production line. We’ll help you eliminate inefficiencies, reduce downtime, and keep your factory running smoothly, all while maintaining the highest standards of quality and reliability.

Streamline Automotive MRO Supply chain

Partner with us to simplify your MRO processes, amplify your operational efficiency, and ensure the right parts arrive just in time, every time.