MRO Systems Integration: 3 Best Practices

Effective and efficient MRO supply chain management starts with data. Last price paid. Manufacturer names and part numbers. Units of measure. Lead times. On Time Delivery rate. Unit Sale Price. Key Performance Indicators. Predictive maintenance. All of it. How your data is managed, analyzed, and interpreted determines the level of success.

Transactional costs are a part of that data set.

In the MRO supply chain, transactions are a significant drag on time and budget. Experience shows that transactional costs associated with processing a purchase order or invoice vary significantly depending on the sophistication of the tracking system. Some estimate the cost of a single transaction at over $125. More reasonable estimates place the cost at $30-50.

For manufacturers, large or small, and facility operators – healthcare, educational, government, etc. – it is not unusual to be working with hundreds and often thousands of vendors. Multiply the transactional costs by the number of transactions processed and the cost of business becomes clear.

Outsourcing the MRO supply chain to an integrated supplier reduces some of the drag on costs. An integrator, particularly one with significant purchasing leverage, can reduce the number of vendors that need supervision. In one example, one company enlisted an independent MRO integrated supply company and saw an estimated $1.2 million savings over a three-year period with more than 24,500 fewer invoices and 24,000 fewer purchase orders. On average, the client processed more than 70% fewer transactions in each year of the three-year contract.

Of course, technology plays a significant role. None of that technology, however, works without integration. If the systems cannot communicate, any efficiency gains are severely hampered. Yes, you can cobble together a process that, on the surface, may appear to be integrated, but is in fact not. The result could mean entering information into two different systems, increasing the likelihood of human error, triggering invoice discrepancy reports (IDRs) that themselves require time and resources to address.

Instead, implementing an MRO systems integration forces a review of existing business processes and will uncover opportunities to optimize where possible. Such a program offers three significant benefits:

- It aligns existing processes with optimal best practices. It helps identify problems that need addressing and defines the scope of what needs to be Also, when a third-party service provider is engaged in managing MRO procurement and inventory, the business processes and system interaction are thoroughly mapped to minimize complexity and maximize gain.

- It provides real time, two-way integration with the transfer of data in both This bi- directional transfer improves visibility to accurate inventory levels, creates faster order processing and streamlines invoice reconciliation.

- Example: In a two-way integration for RFQ (Request for Quotation) process, the customer’s request for parts is electronically sent from the ERP system directly to the vendor or MRO service provider who sources the material in their system and provides a quote back Upon approval of quote, customer generates a PO (Purchase Order) and transmits it to the vendor electronically who proceeds with shipping the order.

- A less efficient one-way integration limits the value gained and may result in an additional burden on the maintenance personnel and a compromised customer experience.

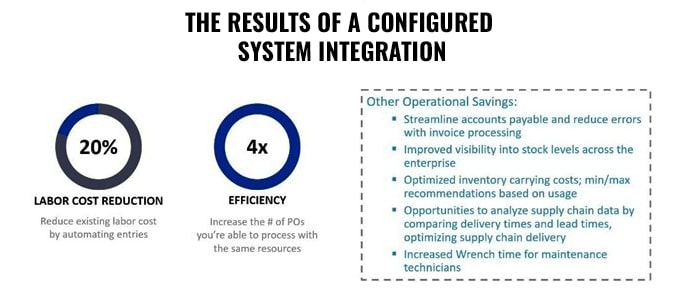

- It increases labor efficiency and reduces manual errors. MRO systems integration is a key enabler for optimal utilization of labor. As data transfer is automated and business processes optimized, personnel can be assigned to other tasks providing higher value for the company and fostering personnel career growth.

- For example, someone responsible for sourcing can now focus on processing bulk orders and work closely with customers to better understand needs, identify critical spares and optimize min/max levels to reduce inventory.

Automatic data transfer also reduces manual data entry errors. Such “fat finger” errors could result in placing orders with incorrect pricing and quantities, driving customer frustration. These errors add complexities to downstream activities like invoicing and reconciliation, and result in unnecessary rework, tying up resources and minimizing productivity.

There are additional benefits to implementing full MRO systems integration, including providing transparency and access to transaction data. The goal is to make MRO as error free as possible to drive value. To get there, here are three best practices.

1. Understand the Need

As you review the business process and determine the data that needs to flow between systems you must identify the system of record for inventory. This is critical to ensure transactions are performed in the system of record as opposed to performing in another system and then trying to interface that data to the system of record.

As an example, if you are performing goods receipt in one system, it is recommended that goods issuing be done in the same system, or it could result in inventory balance discrepancies.

Also, you must define, ahead of time, the expected volume of transactions – like the number of SKUs (Stock Keeping Units) in the storeroom, number of PO lines to be transacted, and the frequency of data transfers to determine optimal infrastructure needed for the interface. If the system cannot manage volume, it will not serve the designated purpose.

2. Engage key stakeholders

The most critical element in implementation of MRO systems integration is having key stakeholders engaged throughout the project. The IT team should be engaged early in the process when planning discussions are initiated. Business teams should be equally engaged to make sure the interfaces are aligned with business expectations.

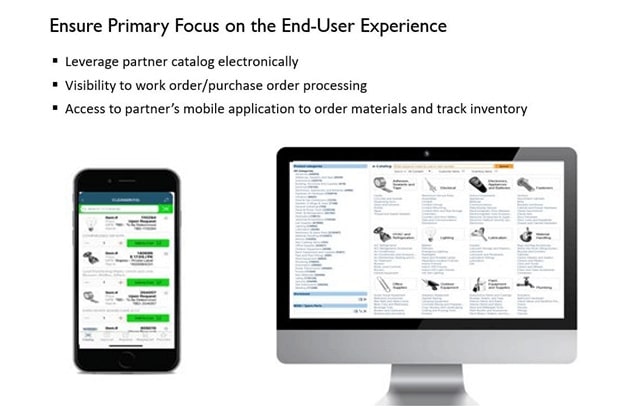

End user training is also important. You can build the most efficient interface in the world but if the users are not well trained it is a wasted effort.

End users should be trained in the system they are transacting in and in how the data transfers between the different systems.

Understanding how the data process flow works helps the end user in utilizing the full system capabilities.

UAT – User Acceptance Testing – is a stage in the project plan which gives business users an opportunity to test drive the interface and identify any adjustments. This stage is intended to make sure the interface is doing what it was designed for. The business should take full advantage of this opportunity to ensure a successful outcome.

3. Budget Resources for Interface Monitoring and Improvement

Lastly, you cannot simply walk away once the system’s interface goes live. Time must be allocated for post go-live hyper care to ensure end users are fully comfortable with the interface. At least two weeks of post go live hyper care is typically recommended. Also, error handling mechanisms and automated reports should be developed to manage any issues proactively and minimize the burden for users.

Interface should help the business as opposed to burdening the business.

When done properly, MRO systems integration adds a significant element of automation and time- saving procedures that further drive down supply chain costs.