Published on

Read time: 5 minutes

Data plays a significant role in any MRO supply chain.

Poor data leads to a cascade of errors, delays, and inefficiencies along the supply chain, impacting everything from procurement to maintenance schedules, potentially leading to downtime and lost profits.

Conversely, high quality data drives cost savings, efficiency gains, and more effective maintenance practices.

As an MRO supply chain management service provider, RS Integrated Supply recognized the critical role of data in MRO operations and embarked on a journey to change data management through innovative technology, culminating in the creation of a new mobile technology, imaging, and artificial intelligence tool that excels in rapid part identification.

The Challenge

Traditionally, managing MRO data involved laborious manual processes ripe for errors and inefficiencies. Identifying parts and standardizing data was time consuming and costly. Once corrected, if not managed properly, old habits will return, creating a repetitive cycle.

Yet, only by understanding what parts are needed, when and how often, can manufacturers begin to fully realize the value of their supply chain.

The Solution

In response to the challenges, RS Integrated Supply introduced SnapPart™ a groundbreaking technology leveraging artificial intelligence and imagery to streamline MRO data management.

SnapPart™ is changing how data is collected by enabling multiple data entry methods, such as voice and text recognition, web search, and barcode scanning. The technology significantly reduces the need for manual data entry while reducing data collection time. And it offers data collection across secure servers ensuring confidentiality and data integrity.

The Implementation and Impact

The launch of SnapPart™ has ushered in a new era of efficiency and accuracy in MRO data management. Instead of manually entering data, the technology harnesses machine learning algorithms to automatically cleanse and standardize data in real time.

At the onset of an integrated supply program, data is initially assessed on availability of information like manufacturer name, manufacturer part number and other attributes. Once cross checked against a global database, an estimated time frame is established for cleansing and standardizing. Following the analysis, the data team deploys SnapPart™ to validate physical items on the storeroom shelf and/or complete missing data points. The objective is to ensure all necessary fields are populated with accurate quality content.

Teams once dedicated to entering data manually, now use SnapPart™ to quickly identify spare parts.

Why digitalization and data help

Digital technologies play a vital role in making MRO procurement more efficient and effective as well. A cloud-based platform such as RS SYNC™ brings the ease and convenience of a retail-orientated experience to the MRO procurement process, allowing users to access an authorized marketplace of products via any web-connected device, including a mobile phone app. It also supports the development of a frictionless procurement process by interfacing with other software such as SAP, Oracle, Maximo and Ariba.

Digital transformation drives data transparency and therefore enables strategic decision-making.

This kind of digital transformation drives data transparency and, therefore, enables strategic decision-making. Appropriate departments can, for instance, access real-time information and analytics about everything from deliveries and inventory to purchase orders and history.

Client Success Stories

The impact of SnapPart™, is already being felt across various industries, including regulated industries like food, pharmaceuticals, and defense. By identifying redundancies and discrepancies in supplier information, SnapPart™ empowers clients to make informed procurement decisions, driving down costs and optimizing supply chain operations.

Recent implementation projects show the versatility of SnapPart™ reduces data collection time by up to 50%, while simultaneously improving data accuracy.

“It’s a multiple step process that allows us to reduce costs because we now have more accurate information and high confidence in that information,” Robert Kline, Chief Technology Officer for RS Integrated Supply, said of the data collection process. It was his team that created SnapPart™.

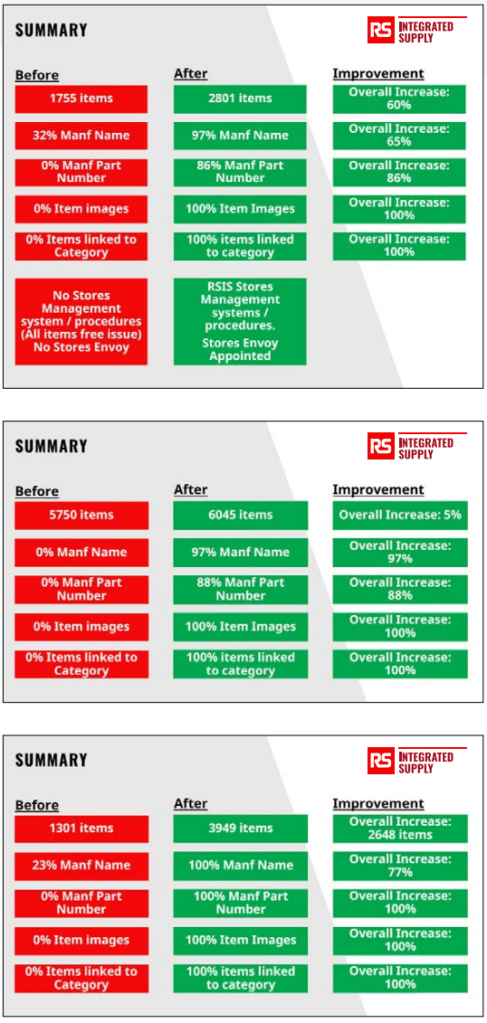

The images below show the results from recent client implementation projects for manufacturers conducted by RS Integrated Supply. In all three, significant improvement was made in identifying manufacturer name, and manufacturing part number while boosting the use of item images by 100%.

In each case, the additional step of tying parts to specific categories helped procurement identify additional savings opportunities by introducing different suppliers at lower price points.

In a fourth project involving a procurement-only client, RS Integrated Supply verified 8,387 items, with 43% improvement in manufacturer’s name, and 60% improvement in manufacturer part number. And like in the other three projects, product classifications and image usage reached 100%. In less than one month after completing the project, the buying team is seeing a significant reduction in non-conformance relating to sourcing and delivery of parts. It means the client is seeing:

- Less returns/ supplier restocking fees

- Improved On Time / In Full delivery performance

- Enhanced stock availability (fewer stock out situations from incorrect parts being delivered)

Overcoming Resistance

While resistance to outsourcing MRO supply chain management is common, SnapPart™ transforms this dynamic by fostering transparency and collaboration between RS Integrated Supply and clients. Through effective communication and partnership-building, RS Integrated Supply demonstrates the value the technology has in driving operational excellence.

By leveraging AI and machine learning, RS Integrated Supply is streamlining data collection processes and improving the quality of the data outputs for further MRO optimization across individual plants or an entire enterprise. It means less waste on unneeded parts, better maintenance efficiency, higher cost savings, and stronger plant reliability.

That is the value of data.